Having completed the build of a CNC plasma cutter which was started by a mate, I decided that it needed a Torch Height Control.

Originally I started out using a Cut40 Rilon Chinese plasma cutter with HF start. This was extremely frustrating to use, it wouldn’t start properly or maintain a constant arc. Using my mates one made no difference, so I bit the bullet and brought a second hand Miller Spectrum 625 plasma cutter.

What a difference, it uses a pilot arc instead of HF and cuts way better than the Chinese one.

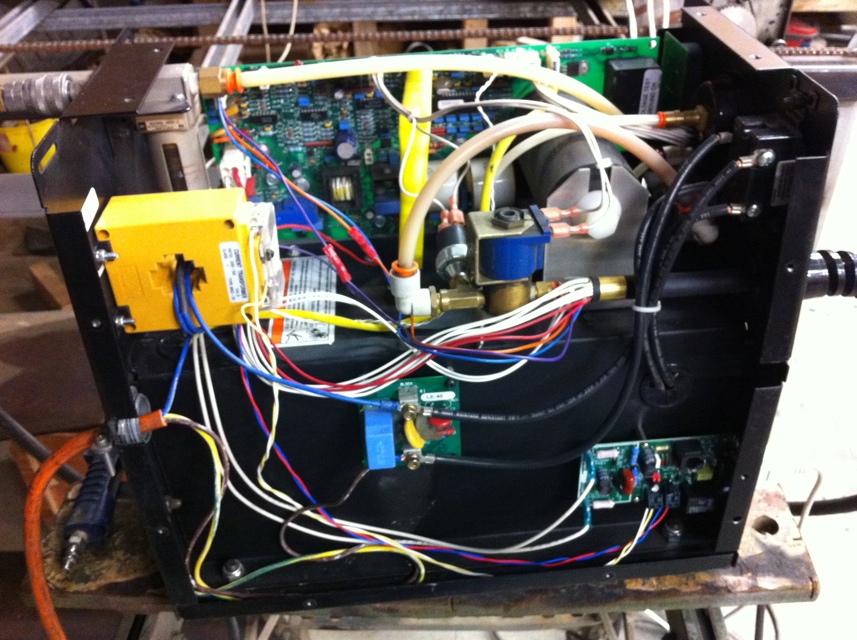

Next I selected the Low Cost Torch Height Control from CandCNC and ordered it from the States. the pictures here show the sensor board mounted inside the Plasma Cutter. It uses the CT transformer with 3 wraps of the incoming AC line.

I am doing the same project for my Miller Spectrum 625 X-TREME. It looks like we are going to have the same setup. (I bought my LCTHC from candcnc.com) I can’t figure out the wiring for the “arc ok” and the board. Do you have any wiring diagrams on how you did this?

Hi Dave,

I’ll dig some stuff out for you on the weekend when I get back home… Antony

Did uu ever figure this ouut

Trying to find exact wiring for the Miller 625 xtream for height control with C & C blade runner.